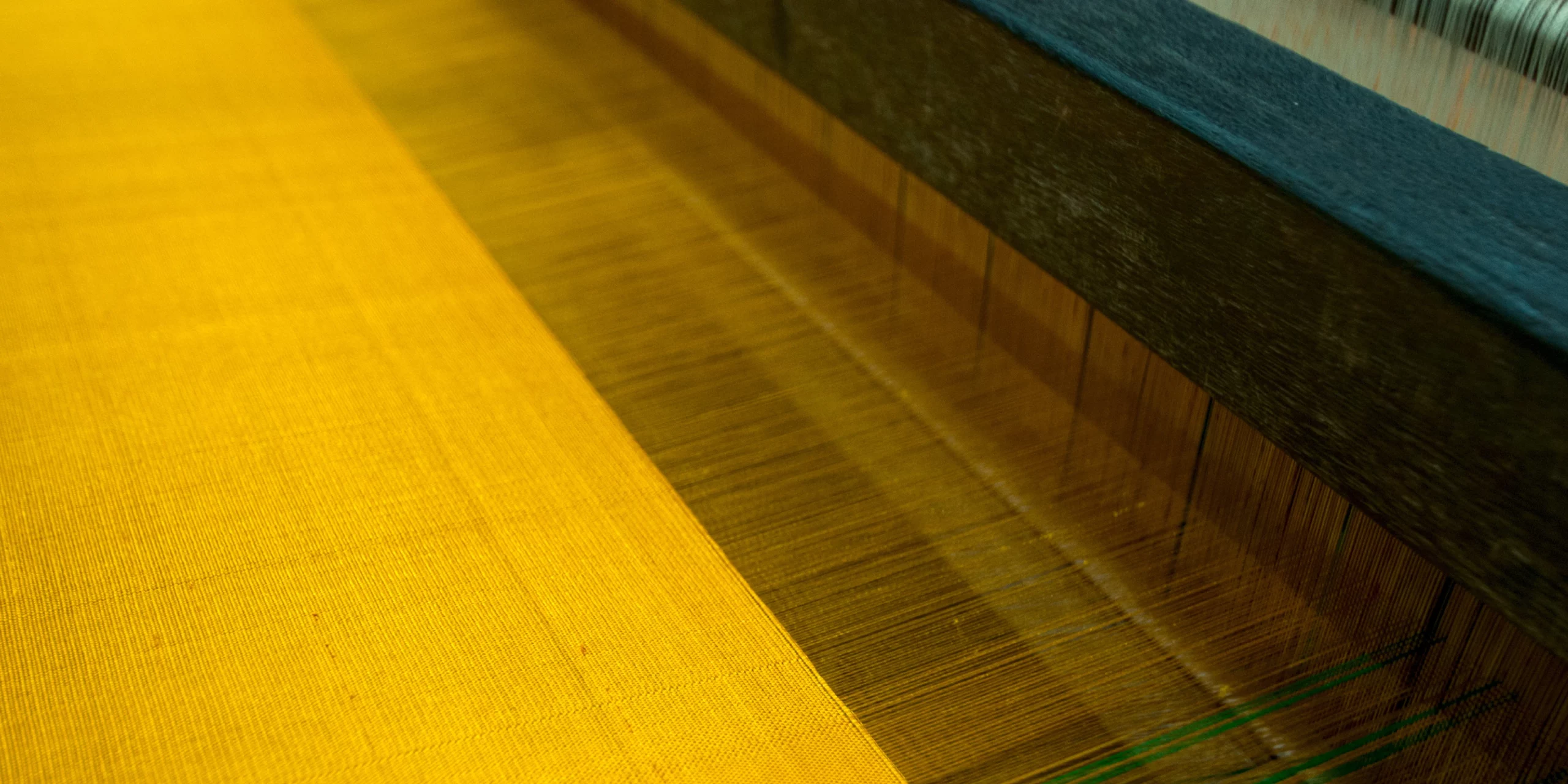

Textile weaving machines are an essential component of the textile industry. The fabric weaving machine is crucial for producing high-quality fabrics used in various applications.

Like all machines, the best weaving machines can suffer from wear and tear, impacting their performance and efficiency. Therefore, these machines are highly complex. It requires regular maintenance to ensure they continue to operate at peak performance.

Whether you’re a seasoned operator or just starting, it’s important to understand how to properly maintain your textile weaving machine. This comprehensive guide will discuss everything you need to know about maintaining a Textile Weaving Machine, from basic cleaning and upkeep to troubleshooting common issues.

5 Ways to Maintain Your Textile Weaving Machine for Optimal Performance

As a professional weaver, you understand the importance of keeping your textile loom machine in good working condition. In addition, it not only ensures the high quality of your products.

Moreover, it also aids in the prevention of costly breakdowns that could shut down your operation for days or even weeks. That is why it is critical to understand how to properly maintain your weaving machine.

1. Regular cleaning: The key step in maintaining a textile weaving machine is to keep it clean. Regular cleaning is essential for a textile weaving machine’s longevity and smooth operation, as dirt, debris, and accumulated lint can interfere with the moving parts. It can result in unnecessary wear and tear.

To prevent it, regularly clean your machines using a soft cloth and an industrial cleaner. Clean the machine after every use, paying special attention to the moving parts, lint screens, and other areas that collect dirt and debris.

2. Lubrication: Keeping a textile weaving machine lubricated is essential to reduce friction and extend the machine’s life. Lubrication is also necessary to cool and minimize friction in spur and worn gears.

High-speed, low-load gear units frequently use low-viscosity oils, like turbine oils. High-quality lubricants are recommended to ensure that your machines remain in top condition.

3. General Inspection: A weaving machine should be regularly inspected to ensure proper operation. Replace any parts that exhibit wear and tear immediately to prevent further harm.

An inspection to determine what materials, labour, and tools are needed to maintain machinery or other equipment in a top working state is a maintenance inspection.

The electrical, mechanical, and instrumentation system components must be examined and operated as part of the maintenance program.

4. Check the belts and tension: Belts and tension are critical components of your textile weaving machines. Thus, proper adjustment is essential for efficient operation. Regularly check the belts and tension to ensure that they are functioning properly.

If you notice any wear or tear, replace the belts immediately, as it could result in issues like tangled threads, uneven fabric, and machine damage. You must follow the manufacturer’s instructions when regularly checking and adjusting the tension.

For instance, excessive tension will make the machine work even harder, and the parts will be prone to more wear and tear. On the other hand, too little tension can also impact the final product’s quality.

5. PLC Control panel: A programmable logic controller (PLC) control panel helps maintain a textile loom machine for optimal performance by controlling and monitoring various machine functions, storing and analyzing data, and providing alarms or notifications in the event of malfunctions or breakdowns.

6. Expert assistance: Operators of textile loom machines can gain from a higher level of expertise, access to specialized tools and resources, and enhanced machine performance and efficiency by working with expert support.

It can include on-site inspections, preventative maintenance, training, spare parts and upgrades, maintenance services, and technical support.

Final Thoughts

In addition to the above-described steps, it is essential to have a professional inspect and maintain your textile weaving machine regularly. The experts at your local textile machinery manufacturer or supplier can provide this service. It aids in catching potential problems before they become significant and costly issues.

Performing a regular maintenance schedule aids in ensuring its longevity and efficiency. If you have any concerns about maintaining your textile weaving machine, consult Paramount Looms.

Paramount Looms is a leading textile weaving machinery manufacturer in Surat, Gujarat. We offer a comprehensive range of weaving machines and textile machinery, as well as expert maintenance and repair services based on our years of industry experience.

Whether you want to purchase a new weaving machine, upgrade your existing equipment, or keep your machines running smoothly?