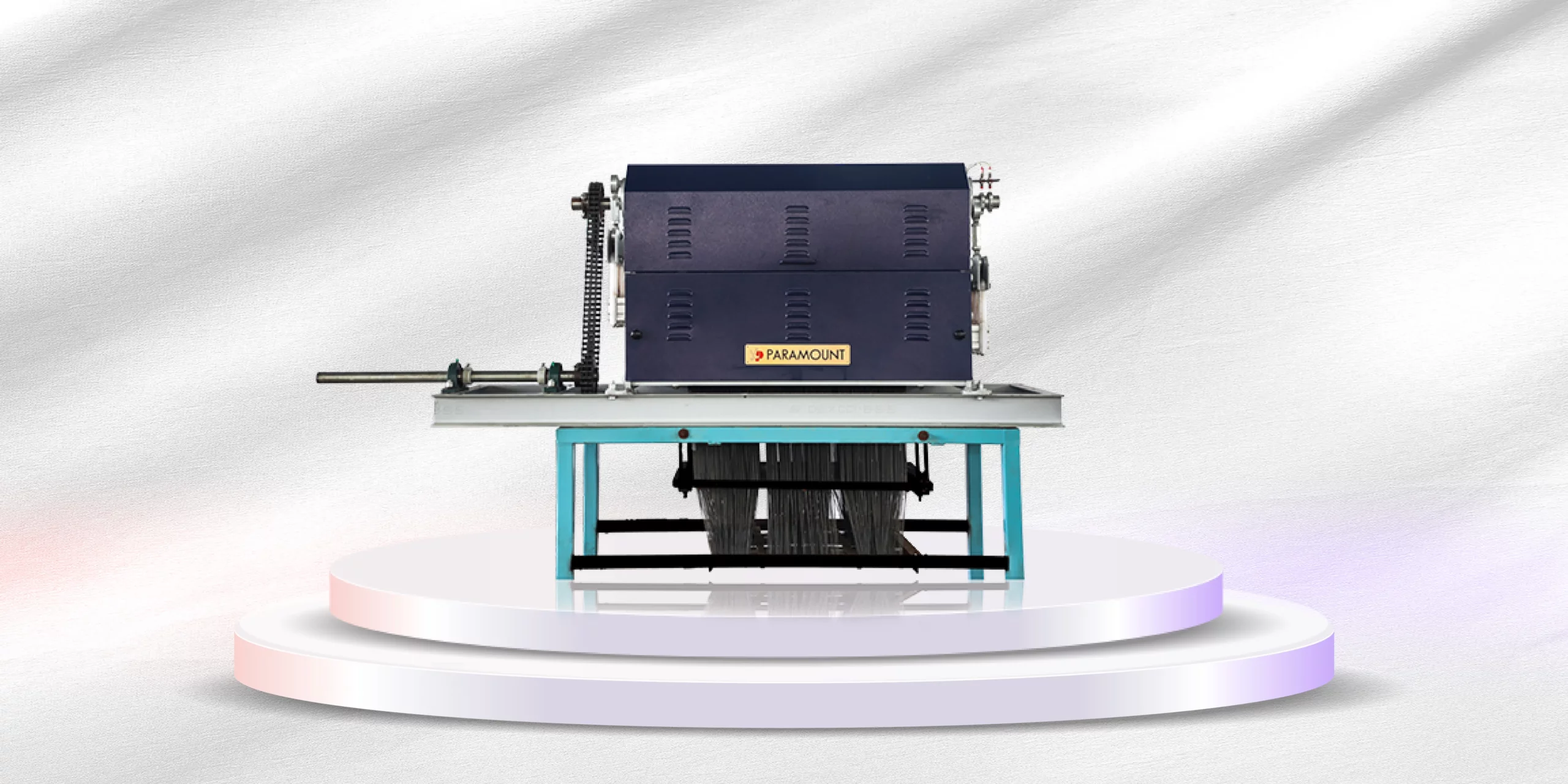

The Jacquard Loom Machine shortens the process of manufacturing jacquard fabrics with complex designs like brocade & damask. This type of woven textile is characterized by its intricate patterns and is a popular choice for clothing, upholstery, bedding, and drapery.

Wait! What exactly is Jacquard fabric?

What does a machine have to do with it?

If you are looking for an opulent, versatile and elegant material, look no further than Jacquard fabric. Let’s discuss everything you need to know about exquisite jacquard fabric. Determine its history and production process to its various benefits.

What is Jacquard Fabric?

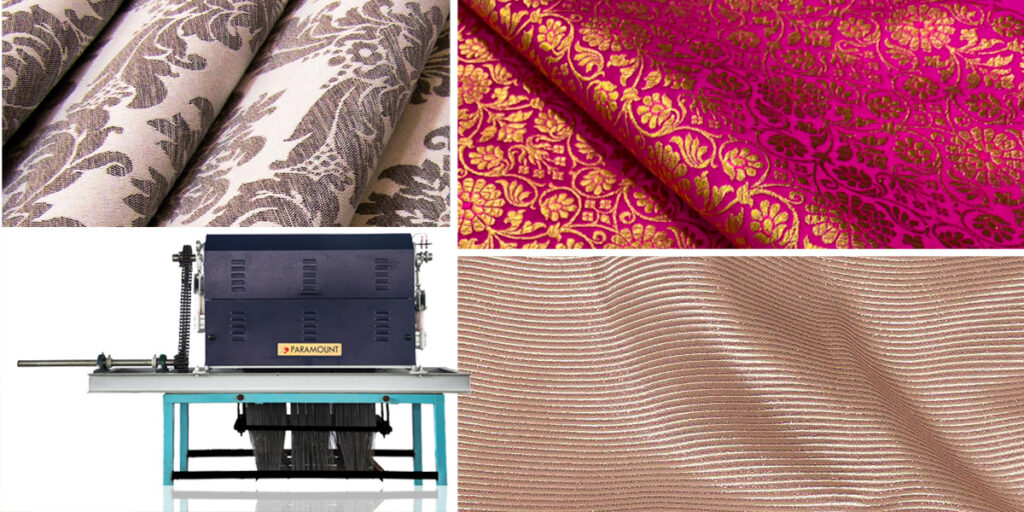

Jacquard fabric is a type of woven textile that has an intricate design woven into it. It’s made using a special loom, which uses punched cards or digital inputs to control the individual threads, allowing for the creation of complex & detailed patterns. Jacquards come in various patterns, such as floral, stripes, chevrons, geometric patterns, and spectacular ornamental damasks.

History of Jacquard Loom Machine

The jacquard loom machine was invented in 1804 by a French weaver called Joseph Marie Jacquard. Today, Jacquard weaving is still used to create high-quality fabrics, and “Jacquard” often refers to the fabric itself.

The Jacquard textile loom has evolved dramatically over the years. Textile manufacturers no longer operate these weaving machines with a series of punched cards, and instead, Jacquard looms are operated by computer programs. It is known as a computerized Jacquard looms.

The Production Process of Jacquard Fabric

- Design Creation: The first step in the production process is creating the Jacquard loom fabrics design. It can be done by using punched cards or digital inputs that control the individual threads in the loom. It allows the creation of detailed designs, which is impossible in traditional weaving methods.

- Warping: The next step is warping, which involves winding the yarns into a continuous length and preparing them for weaving. The yarns are then arranged into a loom in a specific pattern to create the desired design.

- Weaving: Once the yarns are in place, the weaving process begins. The electronic jacquard machine uses perforated inputs to control the distinct threads and create sophisticated patterns. The weft threads are then woven over and under the warp threads to create the fabric.

- Finishing: The jacquard fabrics pattern goes through a finishing process once it has been woven. It can include washing, trimming, and adding a special finish to enhance the sheen and durability of the fabric.

- Quality Control: The final step in the production process is quality control. The jacquard cloth is inspected to ensure that it meets the desired specifications, such as size, pattern, and colour. Any defects are corrected before the fabric is packaged and shipped.

Uses and Benefits of Jacquard Fabrics

Jacquard fabric patterns can be made from various fibres, including cotton, polyester, acrylic and silk. Jacquard weave is a versatile and high-quality material that is commonly used in a variety of applications.

Here are some of the most notable uses and benefits of Jacquard fabrics:

- Clothing: It is often used in high-end clothing, such as jackets, skirts, and dresses, due to its luxurious appearance and durability.

- Upholstery: Jacquard fabric is a popular choice for upholstery, as it is durable and can add a touch of elegance to any room.

- Bedding: It is often used in bedding, such as duvets, sheets, and pillowcases, as it provides a soft and comfortable sleeping surface.

- Drapery: Jacquard fabric is also used in drapery, as it can add texture and depth to a room while providing privacy and light control.

The benefits of producing jacquard fabrics using a jacquard loom machine include the following:

- Increased efficiency: The jacquard textile machine can automate the process of creating complex patterns, reducing the time and labour required compared to manual methods.

- Better quality: The jacquard loom machine allows for high precision and accuracy in producing jacquard fabrics, resulting in improved quality and consistency.

- Cost savings: The jacquard power loom can increase productivity and reduce the need for manual labour, leading to cost savings in producing a jacquard weave.

- Ability to create unique designs: The jacquard loom enables the creation of intricate and unique designs, differentiating the finished fabric and adding value.

- Improved durability: Jacquard fabric produced on a jacquard loom is often more durable than other fabric types, making it a popular choice for heavy-duty textiles.

- Enhanced aesthetic appeal: Jacquard fabric patterns produced on a jacquard power loom can have a luxurious and elegant feel, adding visual appeal to the finished product.

How Lucrative is the Textile Industry with Jacquard Fabrics?

The Global Jacquard Fabric market is anticipated to rise at a considerable rate during the forecast period, between 2023 and 2028. The market is growing steadily, and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

Paramount Looms got you covered if you want to produce Jacquard Fabrics by using a high-speed electronic jacquard loom machine.

Paramount Looms, the top electronic jacquard machine manufacturer in India, is known for producing in the industry, which can contribute to efficient and high-quality production of jacquard fabrics.