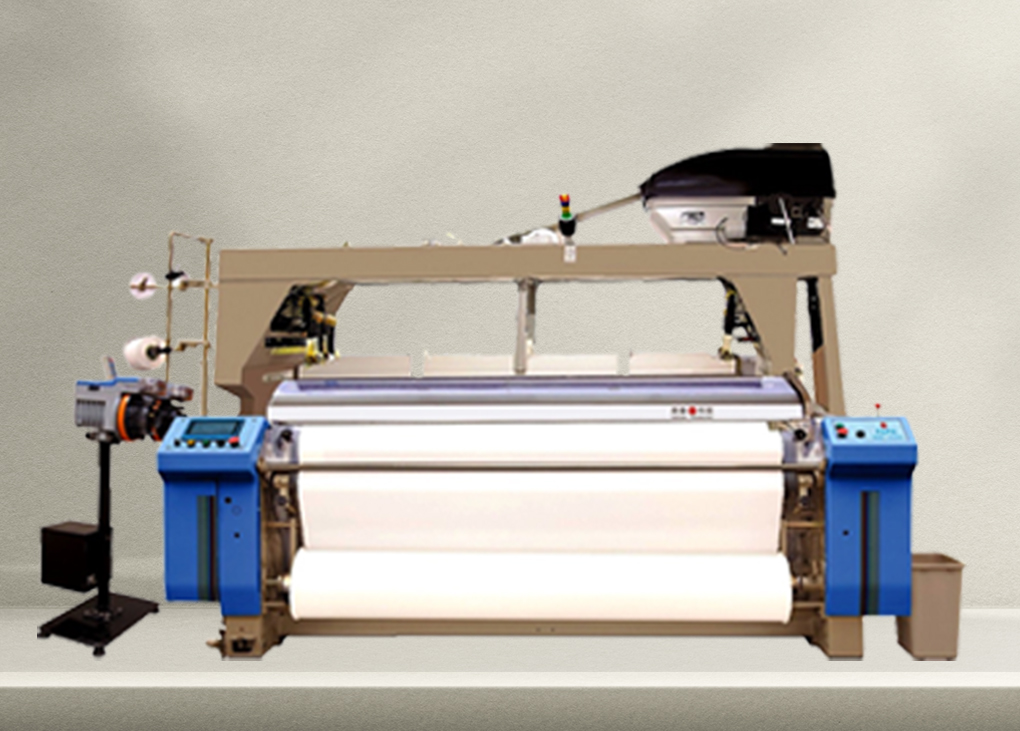

Water jet loom are one of the most versatile and efficient machines used in the textile industry. The water jet loom machine uses high-pressure water jets to interlace two sets of yarns or threads.

It uses a pressurized stream of water to eject threads from a nozzle needle. The loom is controlled by a computer and can produce a variety of patterns and designs.

However, water jet textile machine is also susceptible to corrosion, particularly when used in saltwater environments. It can lead to a shortened working life for the machine and expensive repairs.

This blog provides insight into how to protect your water jet loom from corrosion. You may prolong the life span of your machine & save expensive repairs by adhering to such basic guidelines.

How to Protect the Water Jet Loom from Corrosion?

Corrosion can damage the water jet power loom in a variety of ways. These include-

- Alkaline feed water – Water jet looms are mostly used to manufacture light and medium hydrophobic fabrics. These looms have high weft insertion rates and low energy consumption. You can protect the loom from corrosion by using alkaline feed water. The pH level of the alkaline feed water for the warping and weaving process should be between 7.5 and 8.0. However, the upper pH limit is limited by safety concerns & water having a pH of 10.2 has been used.

- Warp Sizing – The water jet loom machine can only be used on fabrics made of non-absorbent yarns or filament yarns. Roughly yarns need warp sizes which are quite insensitive to water in the weaving process. Nevertheless, it is simple to remove when completing. The loom can be used & kept clean by adding sodium bicarbonate to the water supply.

- Deionized water – Deionized water is a form of purified water used in manufacturing processes. It can cause corrosion in some instances, so use a tin-plated container to prevent it. Glass containers are also ideal as they have low solubility and prevent contamination.

There are numerous ways to shield the water jet power loom from corrosion. Taking care of your water jet textile machine is essential to ensure that it lasts for a long time.

Here are a few simple tips to help you to extend the working life of your water jet loom machines.

- Electrophoretic spraying technology can improve the water jet loom machine’s anti-rust and anti-corrosion properties. The technology allows the looms to have a uniform and complete paint film coverage. The process also improves the loom’s service life.

- Warp Quality – The most effective yarn will have a high elongation at break, making it more resilient to end breaks. It will be able to withstand the rigours of weaving. Warping quality also influences the rate of end breaks. Thus, it is necessary to carefully consider the amount of yarn you plan to use. Air jets are less abrasive than moving metal parts. Therefore, water jet textile machines can reduce wear and tear on warp yarns.

- Warp Breakage Rate – Warp breakage rate is highly affected by the settings of the looms. An important consideration is the amount of water used in the weaving process. Conventional water-jet loom machines consume up to 2 tons of water every day. It is necessary to conduct water quality tests regularly to ensure the best performance of the machine. Likewise, the valves should be easily set and operated.

- Quality of yarn – The water jet power loom is a high-speed weaving machine. It uses water jets to propel the yarn across a 48-inch shed. The machines can weave up to 2,000 meters per pick. Thus, yarn quality must be high enough to avoid breaking ends during the weaving process. The loom can produce more high-quality fabric by reducing breakages.

- Maintenance – Regular maintenance can ensure that your water jet loom machine runs as efficiently as possible. Water-jet looms require large water pressure, so you must ensure that the pump has a large capacity. Otherwise, high water pressure will shorten the functional life of the pump and selector valve. In addition, these machines require less space and are quieter than other types of looms. It is also easy to maintain and causes little to no vibration during operation.

- Reliability- Water jet looms can weave fabric quickly and lay different colors in the weft direction. You can produce high-quality fabrics in a short period. Water jet loom machine are more reliable and space-efficient than other loom types.

Conclusion

To sum up, if you follow these guidelines, your Water Jet Loom will continue to produce high-quality fabrics for many years. Moreover, proper installation & set-up care are critical for optimal performance. Selecting a high-quality machine from a reputable manufacturer is essential for long-term success.

Do you want to produce top-notch fabrics via a water jet textile machine? Contact the trusted and most qualified water jet loom manufacturer in Surat, Gujarat, Paramount Looms.

We make every effort to provide only high-quality information that aids weavers in achieving maximum production at an affordable cost.