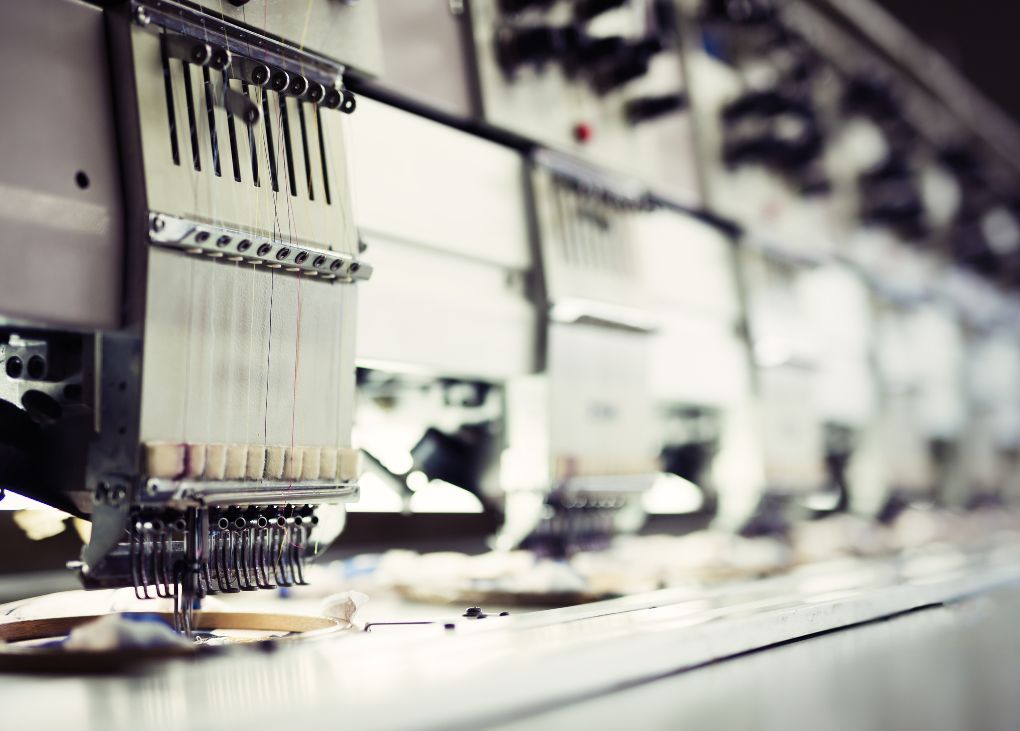

Power looms are one of the most important inventions in the textile industry. They are used to make fabrics with a variety of textures and patterns. The revolutionary tool allows various fabrics with intricate designs to be created quickly and efficiently.

Weaving looms have been around since the first century A.D. Their bulky size and slow speed have caused a great deal of damage to both the human body and the environment. The invention of power looms changed it, and the era of mass production became a reality. Modern power looms are smaller, faster, and more efficient than the early designs.

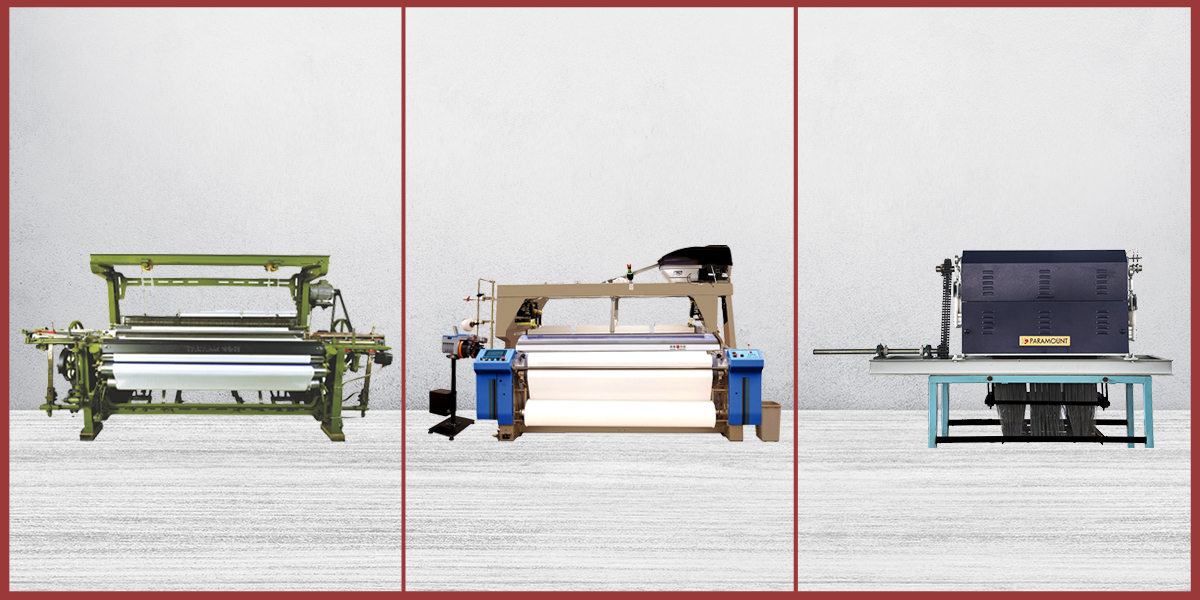

Different Types of Modern Power Looms

As a trusted power loom manufacturer in India, we continuously upgrade ourselves to match the growing demands of the textile industry. We proudly manufacture several high-speed, remarkable power looms that help weavers produce the finest fabrics. Here, we have listed 3 major power looms used in the textile industry. We have also mentioned their advantages and uses to understand these modern looms better.

1). Electronic Jacquard Loom Machine

The Jacquard Loom is a crucial industrial instrument representing a significant advancement in the history of textile production.

A continuous chain of punch cards is used in this machine, located above the loom, to regulate the lifting of individual threads. Every card on the loom corresponds to a hook; depending on whether the hole is punched out or solid, the hook can be raised or blocked.

The Jacquard Loom automated weavers’ work. The weaver had countless ways to “program” the machine and produce complicated fabrics by simply altering the punch cards. An inch of intricate fabric might be woven by traditional silk weavers daily. But a trained Jacquard Loom operator could simultaneously produce about two feet of cloth.

- Advantages of Using Jacquard Loom Machine

- The high-speed electronic jacquard machine does not require dynamic forces as needed in the conventional loom.

- The weft insertion rate in the jacquard loom machine is influenced by the method of weft control.

- The weft insertion rate is very high rather than any conventional loom.

- Requires no need to cut the weft selvedges and no weft wastage.

- Uses of Jacquard Loom Machine

The Jacquard Loom Machine is capable of producing high-end fabrics with intricate patterns. They are used to weave tapestry, brocade, and damask. They are also popularly used to weave patterned knitted fabrics in large quantities.

Contact Electronic Jacquard Machine Manufacturer in India

2). Water Jet Loom Machine

Water Jet Power Loom Machine is used for weaving cloth. The machine uses a water jet to insert the weft (Crosswise threads) into the warp (lengthwise threads). The force of water carries the yarn from one side to another. These machines are produced by only a few water jet loom manufacturers as they are employed to have only water repellent fibre materials. They are majorly used in East Asia. They are characterized by their high insertion performance and low energy consumption.

- Advantages of Using Water Jet Looms

- Water jet looms provide weaving that is quiet and supple.

- Direct movement is made possible by several jet installations. Accurate steering control of loom weaving.

- Operators may be able to continue working well on fewer drives by being flexible while using numerous water jet looms.

- They have a long engine life.

- Water jet loom knitting is easy to do.

- Installation of water jet looms is simple.

- The loom weaving machine does not need a large gearbox.

- Excellent machine manoeuvrability.

- For a knitting loom, low drag and shallow draught are desirable.

- Water loom knitting machines require less maintenance.

- Uses of Water Jet Looms

Only yarns with a hydrophobic character, such as polyester PET, acetate C.A., or polyamides, are appropriate for water jet weaving (6 or 6.6, for example). Hydrophilic natural fibres, such as cotton, nettle, or hemp, should not be used in water jet weaving because they will cause the cloth to become excessively heavy due to excessive moisture absorption.

Although water jet weaving exclusively employs hydrophobic materials, the finished cloth still needs to be dried.

Contact Water Jet Loom Machine Manufacturer in Gujarat

3). Bullet Looms

The Bullet looms driving mechanism is built to produce at a fast rate of speed while maintaining a smooth, inexpensive transmission. Depending on the reed size and fabric quality, the loom can spin at speeds of up to 180 RPM without causing any harm to the weaving or machine parts.

- Advantages of Using Bullet Looms

- Low Power Consumption: Proper ball bearing use facilitates machine parts’ movement, lowering power consumption.

- Low maintenance: Since the majority of the spare parts for the Bullet shuttle loom are constructed of mild steel, and S.G. cast iron, there is virtually no risk that a spare will break.

- Greater Production: BULLET LOOM is built to operate better while requiring less maintenance and downtime. As a result, increasing production speed by weaving using this shuttle loom weaving equipment has shown to be cost-effective.

- High-Speed Weaving: To achieve maximum output, you can raise the RPM of the BULLET LOOM as necessary.

- Heavy Reed Pick: Unlike other Shuttle loom machines, BULLET LOOM machines can weave heavy reed pick.

- Uses of Bullet Looms

Bullet Looms are the most preferred choice of power loom amount weavers. The semi-automatic loom can produce high-end fabrics for daily wear or conventional items. They are frequently used to make sarees, dress materials, suiting & shirting, industrial fabrics, medical fabrics, technical textile fabrics, etc.

Contact Bullet Loom Machine Manufacturer in Gujarat

The modern loom has drastically changed the course of the textile industry. The fabrics are quickly produced with a low manufacturing cost and labour. This has decreased the cost of fabrics in the market and hence pivoted the growth of textiles.

As an efficient power loom manufacturer in India, we make sure to align with the needs and demands of the textile market. Hence, our product range caters to the growing textile market. Want to know more about textile power looms?